PVD coating

Surface coating vaporized under vacuum.

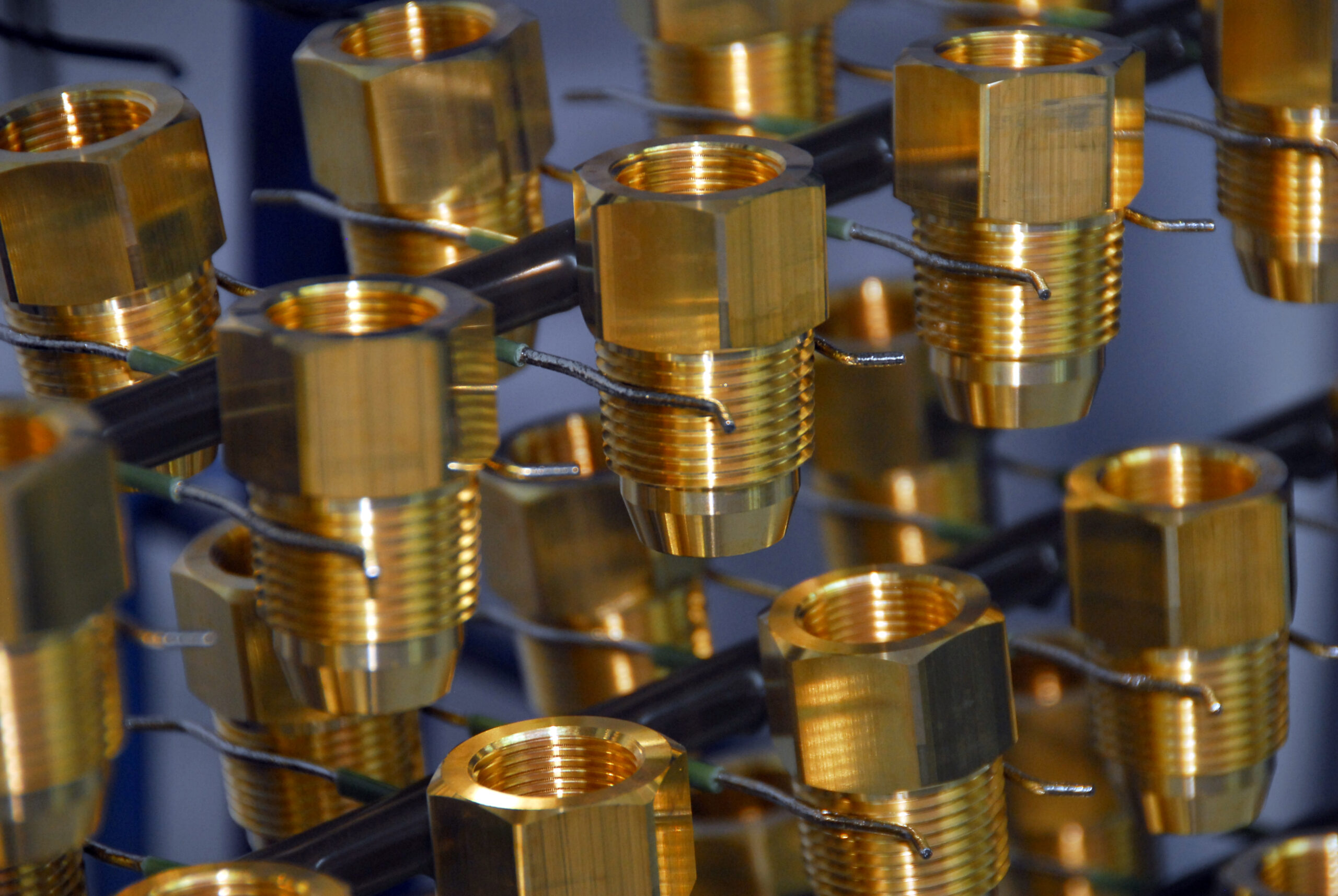

PVD coating

Physical Vapor Deposition (PVD) is a coating process where a surface coating is vaporized under vacuum. The surface coating can consist of metals and/or ceramics and is typically both much harder and more durable than a coating applied exclusively using more traditional galvanic processes. The coating can also be combined with a galvanic undercoating to achieve special properties, including decorative and anti-corrosion properties.

The coating can typically be used against wear, to reduce friction and for decorative purposes. It is possible to apply coating in a wide range of colors.

The coating itself is a dry process and takes place in a vacuum chamber without the use of dissolved metal salts as with traditional galvanic metal coating.

Typical layer thickness:

Between 0.1 and 4.0µ

Appearance:

Chem-Tec Plating A/S offers the colors

- Gold

- Brass

- Chrome

- Copper

- Black chrome

Product overview

Product overview

Contact us regarding PVD coating and find out how we can help you

We help you find the right solutions within surface treatment. Contact us to find out more about how we can optimize your process and deliver a result that matches your requirements.

Write an email to info@chemtec.dk or call us at +45 75 67 92 92.