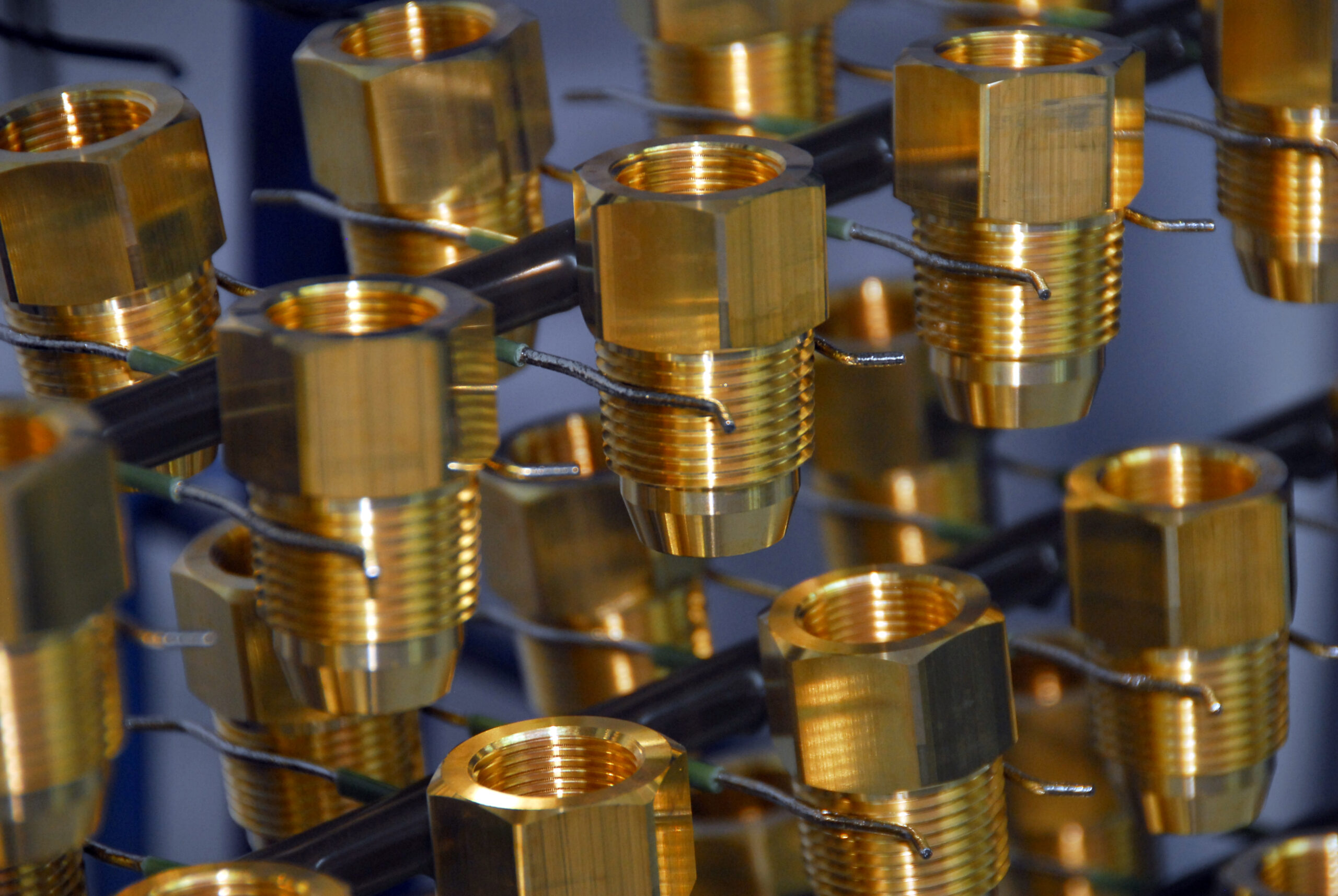

Surface treatment is one of the most important processes in the manufacturing of electronic parts and components. Electronic components are surface treated to improve their electrical conductivity, solderability, and corrosion resistance, among other things.

We offer treatments that are suitable for surface treatment of components used in all types of electronic components.

Plating with gold and silver

Gold is a precious metal commonly used for plating different electronic components. Gold provides a low and stable contact resistance. Gold plating is often used for connectors, switches, circuits, and semiconductors.

Nickel is often used as an underlying coating when using gold for electronics. Nickel prevents the diffusion of other metals into the gold surface, such as, for example, copper. The thickness of the coating is an important consideration when coating electronics.

Like gold, silver is a precious metal that offers numerous advantages in electronics manufacturing. Silver can be an alternative to gold plating on electronics. Silver provides a better electrical and thermal conductivity.

Silver plating is used in several connector applications. Silver has strong soldering properties. A potential disadvantage of silver plating is its tendency to silver migration.

Plating with tin/nickel

The process of tin plating is widely used in the electronics industry for many types of applications. However, a disadvantage of this process is the formation of small metal protrusions called whiskers, which may cause electrical short circuits.

Using a tin alloy for plating in electronics does however offer several advantages. Tin provides excellent solderability, which is important in many electronic manufacturing applications.

The combination of tin/nickel is a good option for coating electronic components, especially for battery switches. The tin/nickel alloy is highly corrosion-resistant and has excellent coverage. It does not require an undercoating for copper-containing materials.

We started coating printed circuit boards in the 1980s. Up through the 1990s and 2000s, we surface-treated billions of springs with gold for telephones.

Today, we offer surface treatment of items for many different segments within electronics, including medical equipment, audio, transportation, and measuring equipment.

We can coat large quantities of electronic components in both loose weight and in reel-to-reel production.

We have two lines of reel-to-reel production. Coating "endless" metal bands allows for one-sided plating from one edge to a controlled depth. It can also be used to lay bands along the tape in nickel, tin, gold, and silver.

Product overview

Product overview

Quality & Production

The goal at Chem-Tec Plating A/S is a high level of quality, which is constantly carried out in the form of continuous quality checks before, during and after production.

Logistics

We are happy to help with the logistics and always strive for the customer's wishes for fast shipping and door-to-door delivery.

Contact us and find out how we can help you

Contact us and hear how we can clarify your questions about surface treatment and can help optimize the process and carry out the task just as you want.

Get in contact by sending us an e-mail at info@chemtec.dk or call us at 75 67 92 92